Case Study: Successful Implementation of Floating Cover Systems in Mining Operations

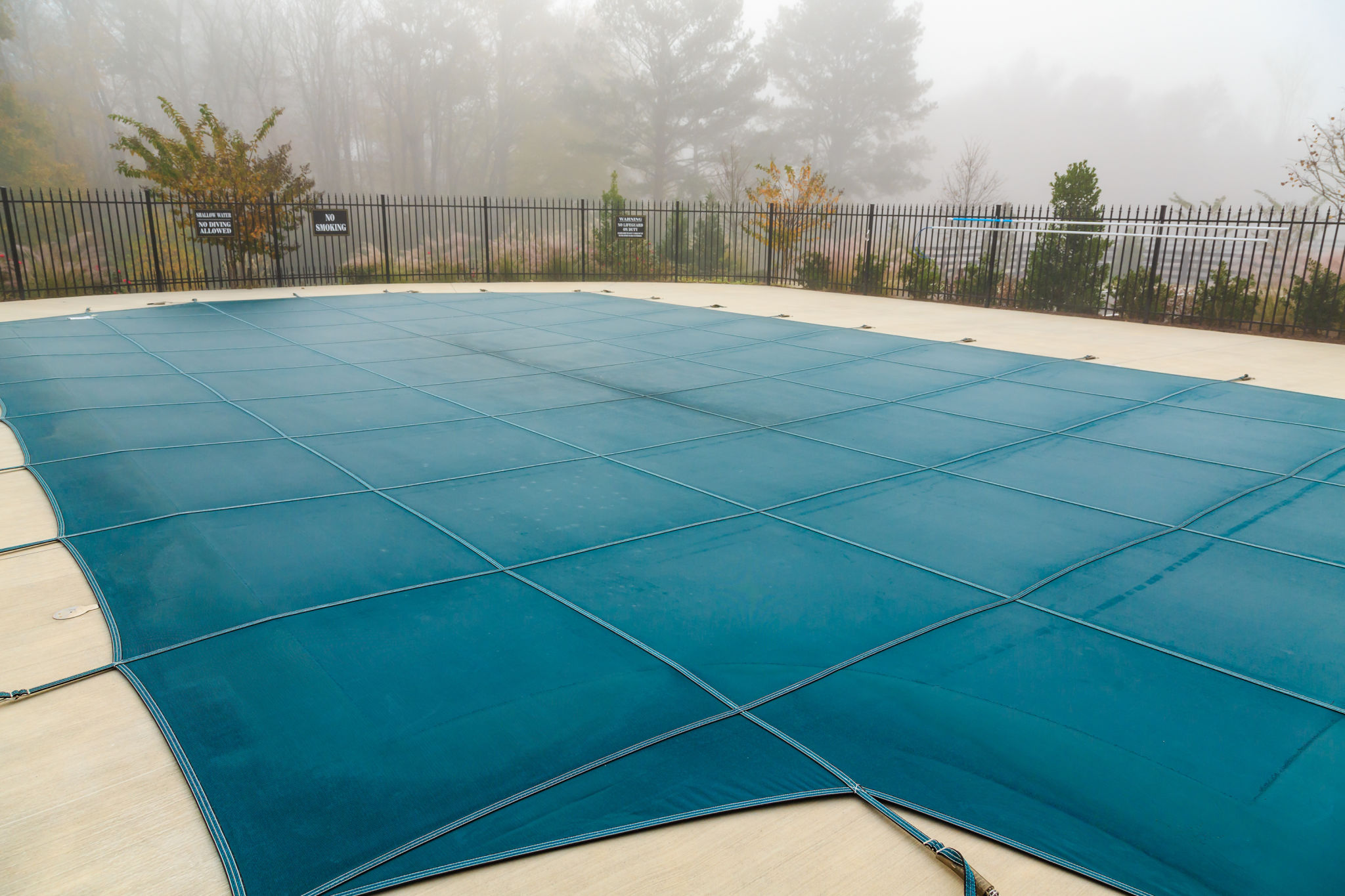

Introduction to Floating Cover Systems in Mining

The mining industry is constantly seeking innovative solutions to improve efficiency and sustainability. One such advancement is the implementation of floating cover systems. These systems have proven to be a game-changer, particularly in managing water resources and reducing environmental impact. In this case study, we will explore how floating cover systems were successfully integrated into mining operations, highlighting their benefits and effectiveness.

The Challenge of Water Management in Mining

Water management is a critical aspect of mining operations. Mines often require large quantities of water for various processes, and managing this resource sustainably is a significant challenge. Without proper control, water can become contaminated, leading to environmental degradation and increased regulatory pressures. Prior to the adoption of floating cover systems, many mining operations struggled with evaporation losses, contamination risks, and compliance with environmental regulations.

The Implementation Process

Implementing floating cover systems involved several key steps:

- Assessment: An initial assessment was conducted to determine the specific needs and challenges of the mining site.

- Design: Customized designs were created to fit the unique topography and requirements of the site.

- Installation: The installation process was carried out with minimal disruption to ongoing operations.

- Monitoring: Ongoing monitoring was established to ensure the systems functioned as intended.

Benefits of Floating Cover Systems

The introduction of floating cover systems brought several benefits to the mining operations:

- Reduced Evaporation: By covering water bodies, evaporation losses were significantly minimized, leading to more efficient water use.

- Contamination Control: These covers acted as barriers, preventing contaminants from entering water storage areas.

- Improved Compliance: The system helped mines meet stringent environmental regulations regarding water management.

Environmental and Economic Impact

The environmental benefits were substantial. By reducing evaporation and contamination risks, floating cover systems contributed to more sustainable mining practices. Economically, mines saw a reduction in costs associated with water loss and environmental penalties. Furthermore, the improved water management practices enhanced the mines' reputations among stakeholders and regulators, fostering better community relations.

Case Study Example: A Success Story

A leading mining operation in Australia implemented floating cover systems across its sites. This initiative led to a noticeable reduction in water loss by up to 80%, translating to savings in water procurement costs and lessened environmental impact. The success of this project has set a benchmark for other mining companies looking to enhance their sustainability practices.

Lessons Learned and Future Directions

This case study highlights the importance of adopting innovative solutions for sustainable mining. The successful implementation of floating cover systems demonstrates how technology can address long-standing challenges in resource management. Moving forward, it is crucial for the industry to continue investing in such technologies, promoting environmental responsibility while maintaining economic viability.

Conclusion

The integration of floating cover systems in mining operations exemplifies a significant step towards achieving sustainable practices. By overcoming challenges related to water management, these systems not only protect vital resources but also enhance operational efficiency. As the industry continues to evolve, embracing such innovations will be key to ensuring a balance between development and environmental stewardship.